Everything you need to know about Timber Bi-Fold Doors

Do you have a spectacular view of the city, a lovely garden or patio or even an outdoor landscape? Do you get the feeling that your existing doorways to these areas are simply not conveying the true impact of the view? Transform the look and feel of your home and incorporate aluminium bi-fold doors. Step outside of your comfort zone and consider bi fold doors. They provide one of the best ways that you can enjoy both outdoor and indoor living.

Bi-fold doors are one of the best ways to allow a homeowner to maximise a wide doorway. These special doors can be configured to integrate multiple door panels, typically two to eight, depending on the width of your doorway. Depending on the configuration they either stack to one or both sides.

Open plan living is an enviable feature of modern homes, and with their ability to be installed in very wide openings, a bi-fold door allows you to connect your living room with an outdoor entertaining area by essentially easily removing entire wall between the two spaces. This allows you to, in many cases, have your kitchen, living, dining, and outdoor areas all linked and open, offering a sensational aesthetic to your home. Even when they are closed, they offer a terrific amount of light and a near unobstructed view. This would be one of the most common ways to use a Bi-Fold Door.

How Do Timber Bi-fold Doors Work?

Interior and exterior bi-folding doors both use a simple track system that runs along the panels, which are connected on a train. The doors work by folding in on themselves and then gliding along the tracking system with the help of a series of wheels or a lower tracking system, which both lead to a smooth motion and quiet operation.

Bi-fold doors generally come in pairs, with two doors folding to one side or with four that part in the centre with two doors folding back to either side. Your bi-fold doors will usually come with all tracking and fittings already installed, can be opened either inwards or outwards. It’s this kind of flexibility that has led to their popularity in recent years amongst open-minded homeowners.

Most bi-fold doors will have anywhere between two and seven panels, all of which will be connected with hinges and attached to the roller track at the top or bottom of the door (or both). They are remarkably easy to operate, though it’s advised that you don’t get too carried away as if you use too much force you could end up pulling the doors out of the tracking system

In many homes, there are living and dining sections that next to each other but divided by a wall, or not divided at all. Sometimes, open plan isn’t always the best option, as you may wish to improve privacy or entertain two different groups at once. Installing bi-fold doors internally as a divided wall is a great way to make one large room into 2 without making the rooms seem boxed in or small. The glass panels keep noise transference to a minimum, but allow visibility into the adjoining room. This is great for families with small children for example, as you can have a dinner party in one room, with the kids table in the connecting room, where you have total visibility but can also enjoy some peace & quiet. Another example is if you work from home, where you could segment off a section of the living area during business hours, but then open it back up the rest of the time.

Above we talked about connecting two rooms, but by installing multiple bi-fold doors, you can turn your dining room into an outdoor entertaining area, simply by removing the walls around it. Depending on the layout of your home, you could install 2 or 3 bi-fold doors to make up the walls of the dining area, then when the weather’s beautiful, you can easily remove all the walls and dine alfresco!

If you’re lucky to have a bedroom that gazes upon the abundance of natural beauty, then why not take full advantage of it. This is one of the most beautiful ways to use Bi-fold doors. When it’s perfect weather, you can remove an entire wall to make the most of the sunshine and cool sea breeze, and even when it’s not the best conditions outside, you’ll have an unobstructed view of the reason you’re still in your PJ’s watching Netflix in bed.

Choosing the right bi-fold door for your renovation project can be both exciting and overwhelming. You’ve got a grand vision for your new space and a lot of questions about products, materials and styles. Although your contractor may make suggestions as to which material or brand to use, ultimately the final decision is up to you.

Bi-fold doors come in a range of sizes, glass types, colours and materials. One of the most important factors to consider when selecting the right bi-fold doors is which material to use for your project. When making your selection, you should note that not all materials are created equal. In fact, each of these materials has different properties which help to determine their price point.

Timber is one of the oldest building materials known to man. It is all natural, non-toxic and a high quality, timber doors can last many, many years. Timber products come from FSC certified forests which means that they are harvested from forests that are responsibly managed and farmed. Wood that comes from an FSC certified forest is replaced with new growth for future use.

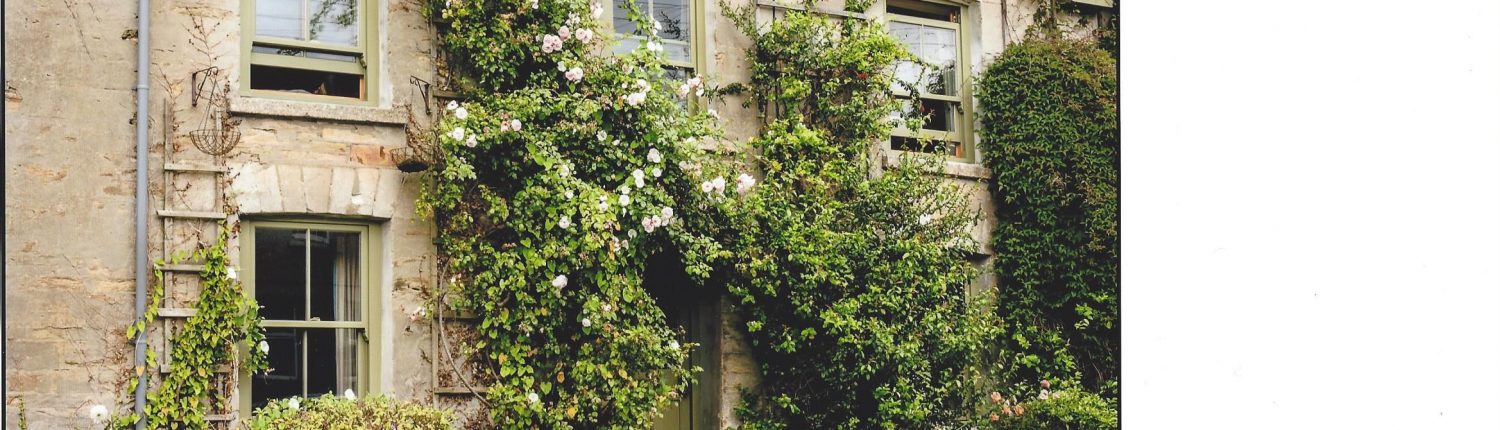

Although more expensive than PVC, selecting timber for your bi-fold doors can greatly elevate the look of your project. it may also help to create an ambiance that is warm, welcoming and even rustic.